A chain is only as strong as its weakest link. The same goes for your business and the processes within it.

If one process within your business is lagging, it can have a knock-on effect all the way down the chain.

Take onboarding, for example.

If your delivery firm is slow to hire new drivers, you can end up with a pile of undelivered orders, battling with angry customers, and shelling out big bucks to store goods that you can’t get out fast enough.

It’s wise, then, to carefully comb through your business processes to work out where you can improve the flow of operations to boost your overall productivity.

To do this, you’ll need to know the steps to coordinate process improvement, without throwing everything off balance.

In this article, you’ll learn what to consider when improving your processes, along with the vital process improvement steps to streamline your performance to stabilize your business all-round.

What to Consider Before Taking Process Improvement Steps

Whether you’re creating a new process or streamlining an existing one, it’s important to devise a process improvement strategy that prioritizes each workflow according to the goals you’re looking to achieve.

The order in which you address systemic inefficiencies will determine the outcomes further down the pipeline.

In this sense, it’s smart to consider your desired outcome and reverse engineer smoother operations.

For example, if you want to improve customer retention, you need to look at the processes that contribute to a high drop-out rate.

Say, you find two major problems — monthly deliveries are always late and many popular products are often out of stock. Upon inspection, you notice that customers mainly complain about deliveries. It makes sense to start on the delivery process as this is having the biggest direct effect on the customer.

The second most important consideration is how you plan to improve processes.

While many business owners think that process improvement simply speeds up workflows, your process improvement initiative can streamline your systems in multiple ways.

Of course, fewer bottlenecks and slicker operations means faster workflows. However, you’ll also find that more efficient solutions result in fewer mistakes, contributing to cost savings and wastage reductions.

For example, business process automation software, like frevvo, digitizes paper processes. This cuts revenue risk by half.

Alternatively, you may look to improve a work process to provide higher quality results. This can lead to better team collaboration and improved customer service.

Finally, before embarking on a process improvement project, think about the time, budget, and resources available. Consider which potential improvement will have the most impact on the overall workflow without breaking the bank.

7 Process Improvement Steps to Streamlined Operations

To improve processes within your organization, it’s vital that you learn how to identify problems, analyze operations, and devise long-term solutions.

Follow this walkthrough to turn inefficient processes into slick operations in seven simple steps.

1. Define the Issue

First, identify the issues that occur most frequently or cost your business the most — whether that be time, money, or resources.

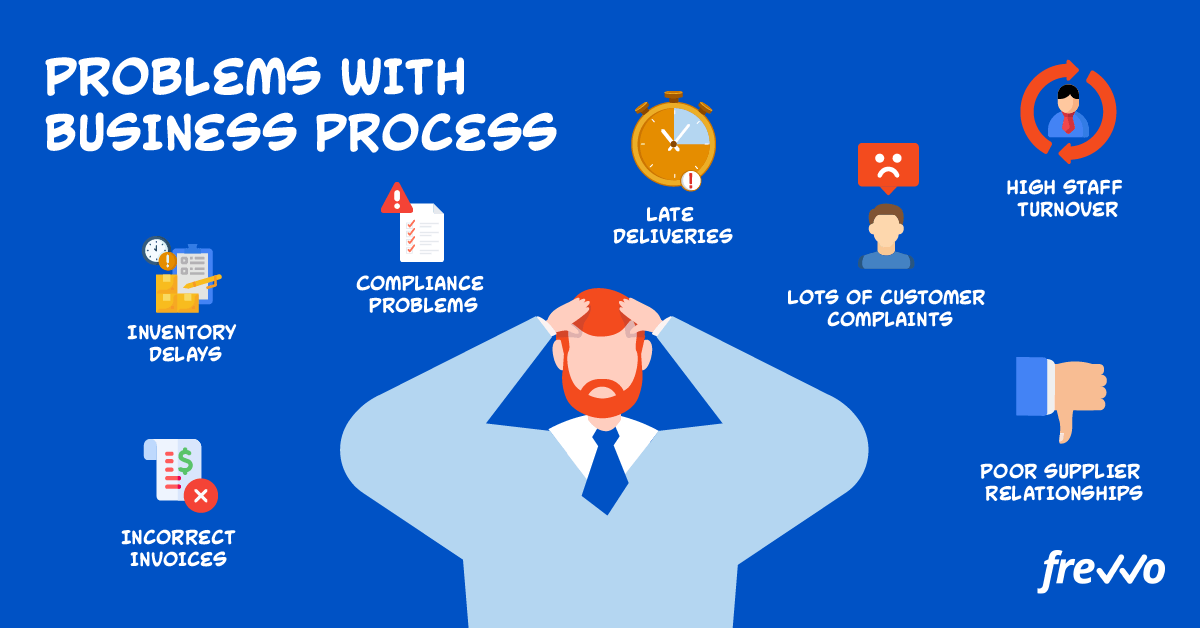

Look for the symptoms of bottlenecks and inefficiencies. These usually manifest as:

- Long wait times or delays

- Continuous errors

- Unhappy customers

- High staff turnover

- Unexpected costs

- A backlog of work or stock

- High levels of wastage

By identifying key problems, you can pinpoint the processes that contain inefficiencies to iron out these bottlenecks at the source.

Take beauty retailer, Yves-Rocher.

The company had a problem with new employees working for several weeks without getting paid. At first, this appeared to be a payroll issue.

However, on closer inspection, it became clear that slow manual paperwork processing meant onboarding paperwork wasn’t processed quickly enough.

By identifying the problem and analyzing the issue, Yves-Rocher was able to pinpoint the right process that needed improving. This meant resources were directed straight to improving the onboarding process, rather than wasting money on shaking down the payroll system.

To analyze the issue in depth, consider how these problems are affecting your business.

Are you losing money? Staff? Time? Perhaps the issue affects your supplier or customer. Maybe the problem is taking up too much manpower or using more resources than you accounted for.

Proper analysis of the blockages can help to better guide your process improvement effort later.

2. Map your Process

A process map will help you to understand how your process flows. By knowing the actions, stakeholders, and deliverables of each phase, it’s easier to notice a blockage.

First, map the scope of the process. Note when the process starts and finishes. Mark down the goals of the process and the scenarios in which the workflow is applied.

Next, map the actions taken and deliverables produced at each step, along with the stakeholders involved in moving the process through each phase.

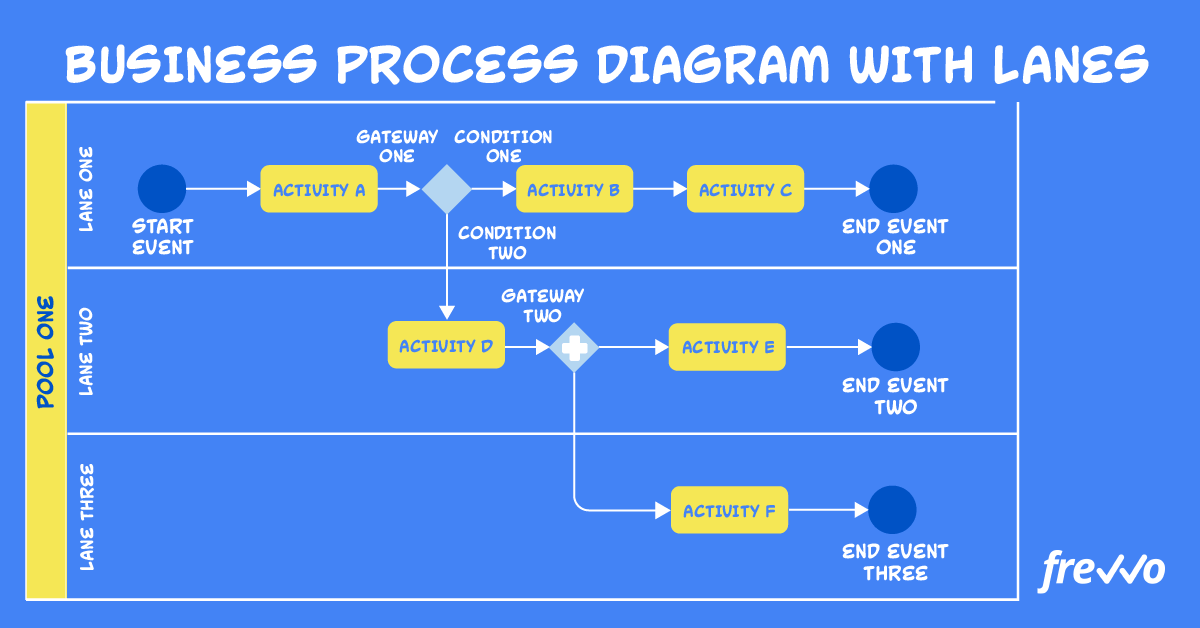

If you’re looking for an easy-to-understand process mapping technique to visualize your processes, try Business Process Modeling Notation (BPMN).

An extremely popular process mapping methodology, BPMN maps each process as a simple-to-read flowchart. Easily understandable by both humans and software, a BPMN process map is ideal for those looking to digitize processes.

3. Identify Your Metrics

How will you know whether your inefficient process has become an efficient process if you don’t measure its success?

Define your metrics early so that you begin measuring your process improvement effort from the get-go.

Consider the measurable variables that show how much a problem is affecting each existing business process, along with how well the solution works.

For example, if you’re looking to remedy late deliveries within the distribution process, your metric could be the ‘weekly rate of late deliveries’.

To delve even deeper, you may look at the rate of late deliveries per reason (broken truck, missing stock, sick staff, etc) or the rate of late deliveries per driver. This can help to identify deeper root causes for continuous process improvement over time.

Remember to identify metrics for each stage of the process, not just the problem area. While symptoms of a problem may occur in one phase, the root cause may lie further up the chain.

For example, deliveries may be late due to a lack of warehouse staff picking and packing items for delivery. Only by measuring truck packing times per shift will you notice that trucks are packed late on shifts with fewer team members.

4. Analyze your Process

Look at every stage individually to see how well it is performing against your metrics. By doing this, you should be able to identify delays or blockages at each step.

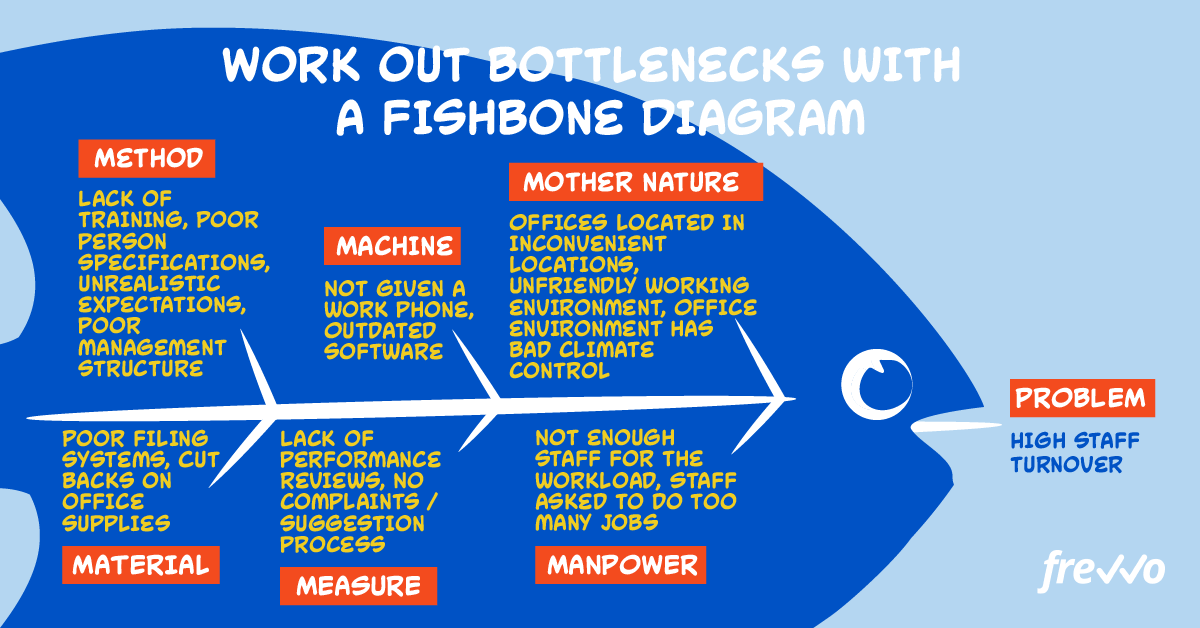

First, draw a Fishbone Diagram.

A fishbone diagram helps you to consider where bottlenecks exist in every facet of each step.

You need to consider:

- Method – What’s inefficient about the way the step works?

- Mother Nature – What’s limiting the process environment?

- Materials – Do you have enough appropriate resources?

- Machine – Do you have the right tools and technology?

- Manpower – Are there bottlenecks in staffing?

- Measurement – Are you measuring success accurately?

Next, you need to get to the bottom of these inefficiencies.

Understand that the symptoms of bottlenecks may move up and down the process chain. The key to successfully improving processes lies in identifying the root cause of issues, rather than simply fixing symptoms.

Imagine you turn on your faucet and no water comes out.

You inspect the water pipe to find that it’s burst. You replace the pipe.

However, you come back tomorrow and turn the faucet on — no water. The pipe has burst again.

Do you replace the pipe again? Of course not — you look for the reason the pipe keeps bursting.

In this case, the burst pipe is just the symptom of a deeper root cause. The root cause could be too much water pressure, frozen pipes, bad installation, and so on.

You need to find the root cause to stop the pipe bursting in the future.

In the same way, you need to find the root cause for problems in your processes. That way you can create a long-lasting solution that will actually fix those bottlenecks and inefficiencies.

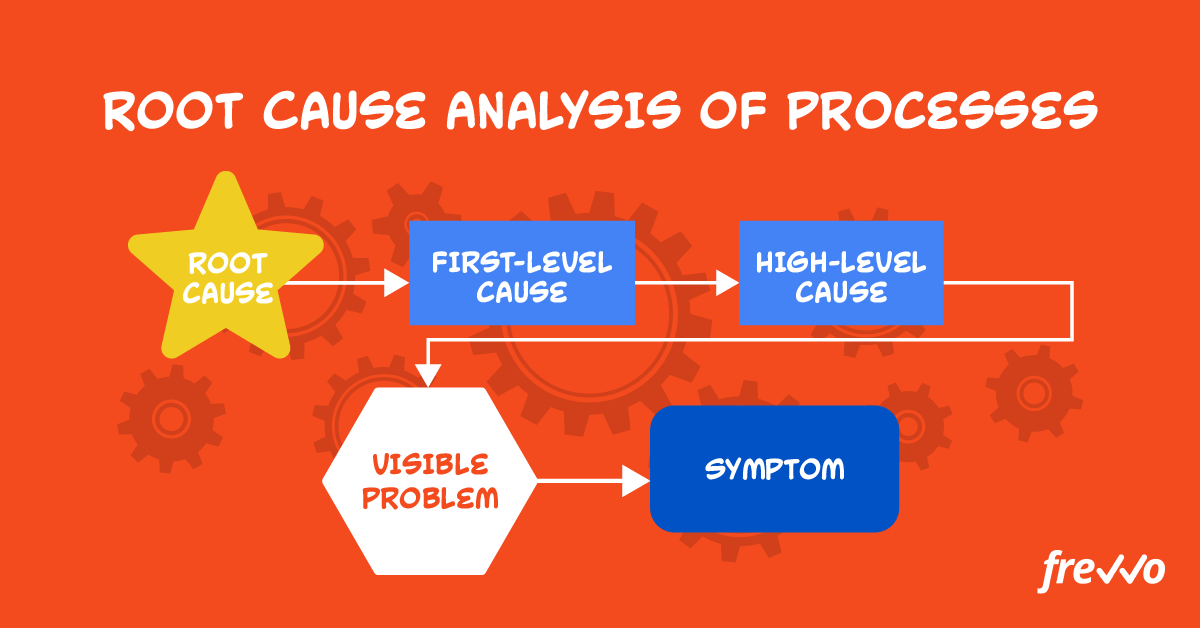

Try performing a Root Cause Analysis.

- Start with the symptom and ask yourself what the visible problem is.

- Move to the first-level cause of this problem.

- Delve deeper to consider the higher level causes of this issue.

- Dig one stage further and you’re likely to find the root cause.

For example, imagine that you’ve been refunding 70% of customer delivery fees for late deliveries.

Let’s analyze this by asking ‘why’ four times:

- Why are you refunding money? Deliveries are constantly late.

- Why are deliveries late? There are not enough delivery drivers to deal with the workload.

- Why are there not enough drivers? The workload has increased yet there are no new hires.

- Why has nobody been hired? Nobody has given the delivery manager a budget or authority.

The solution is that someone needs to authorize the delivery manager to hire new staff and provide the budget to do so.

5. Counteract Root Causes

Now that you’ve located your bottlenecks and identified the root causes, you can build a process improvement initiative that cuts out these problems for a more efficient process.

Solutions should directly counteract root causes, instead of temporarily soothing symptoms.

Let’s look at solar energy installer, Activ8, as an example.

Activ8 noticed that sales personnel weren’t closing deals.

When analyzing the issues, the solar company found that there were countless mistakes in sales paperwork, quotations took far too long, and customers changed their minds in the later stages of the sales process.

While these issues seemed like isolated problems, when Activ8 analyzed the whole sales lifecycle, it was clear that the entire process was lengthy and cumbersome. There were so many potential points of failure as the process was super inefficient.

A salesperson would inspect the customer’s home and create a report by hand. They’d head back to the office and pass this information to the office staff, who would draw up a quotation and send it by snail mail to the customer. Plenty of time for a customer to pull out and lots of room for errors and lost paperwork.

It was clear that the root cause of all these issues, from the slow sales cycle to the paperwork errors, was the clunky manual sale procedures.

To fix the issue, Activ8 deployed frevvo.

Using frevvo’s business rule calculations, installers can now carry out on-the-spot calculations for accurate pricing, materials estimates, and grant eligibility in the customer’s home.

Since frevvo connects directly with Activ8’s payment processor, customers can pay there and then — no time to change their mind.

Frevvo’s digital forms are completed by the customer in real time and then automatically emailed to the office and the client. No more errors, no more lost paperwork, and a super slick sales cycle.

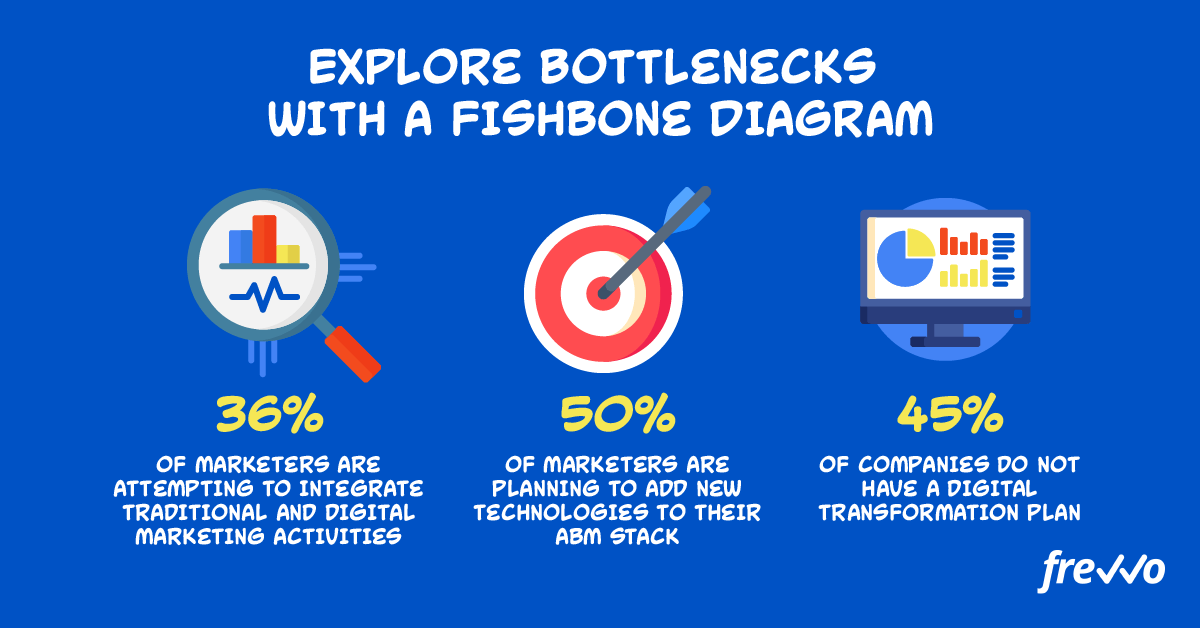

6. Digitize and Automate Your Processes

When your processes rely on hard paper copies, there’s plenty of opportunity for lost paperwork, incorrect data entry, and outdated audit trails.

You’ll find that process digitization and automation saves you and your team time, money, and resources.

Not only do automated digital processes run quicker, you’ll pay lower labor costs thanks to reduced data entry and less remedial work.

On top of that you’ll see better employee performance, more resilient business practices, and higher levels of process efficiency.

Take document digitization. 40% of business decision-makers believe that digitizing documents improves employee productivity.

Now, consider digital signatures. 72% of business decision-makers consider e-signatures as vital to business continuity and agility.

Let’s look at process automation.

42% of business leaders agree that task completion is quicker with automation. Plus, 45% of all paid activities can be automated with business process automation software.

All things considered, it’s clear that there’s huge cost-savings to be made by addressing manual processing within your operations.

7. Track and Maintain Progress

Continuous process improvement requires you to track your new process.

Though you may have defined your metrics at the earlier stages, make sure you have tools in place to measure these metrics. Know how often you’ll measure progress and who’s accountable for measuring levels of success. Make sure there are protocols in place to prevent bottlenecks reoccurring.

Take frevvo’s automated approval workflow software, for example.

While approvals are automatically routed to the correct approver, this isn’t the only measure taken to guarantee success.

Automatic notifications and reminders prevent approvers from forgetting to sign documents, while approval tracking keeps an audit trail. That way approvers are held accountable if they bottleneck the system.

Conclusion

There’s always room for improvement, especially when it comes to organizational processes.

The key to real process improvement lies in identifying root causes, rather than simply addressing symptoms. That way, you’ll find it far easier to create long-term solutions that keep bottlenecks at bay.

By employing these process improvement steps, you’ll not only find that you save time and money. You’ll also see the results on the faces of happier suppliers, staff, and customers.

Don’t settle for clunky processes. Instead, sign up for a free 30-day tral of frevvo.