Do you need to streamline procurement in your organization? Are you wondering what best practices would help you improve purchasing processes further?

Well, I can only imagine the weight on your shoulders.

Your company needs to source goods and services to deliver what’s been promised to customers. Organizing it all – not to mention, doing it faster and faster while continually reducing costs – rests entirely with you.

And that’s not the only pressure you’re under. Even the shortest supply chain delay might bring the entire production to a halt.

But I can show you how to avoid those disruptions.

After reading this guide, you’ll understand the most common challenges and bottlenecks in your procurement processes. You’ll also learn what best practices in procurement to implement to eliminate those bottlenecks once and for all.

So, to begin, let’s look at what goes wrong in a typical procurement process.

Common Supply Chain Bottlenecks

If there’s one thing common to all procurement processes is that they are complicated beyond reason.

The sourcing process:

- building supplier lists

- managing vendors

- negotiating contracts

- acquiring the goods

- getting it all delivered on time

- and more!

…all requires constant and streamlined cooperation between far too many stakeholders to keep the process smooth and seamless.

As a result, bottlenecks arise, causing delays and disruptions affecting the company’s operations and the bottom line.

Many of these bottlenecks might seem unavoidable at first. Luckily, that’s not the case. You can eliminate many of those challenges by implementing simple best practices.

Before we talk about that, though, you need to understand where those bottlenecks typically appear.

To do that, we need to turn to the findings of the 97th Annual Institute for Supply Chain Management Conference. During the event, participants – sourcing and procurement managers – completed a short survey, asking where they feel the biggest “pinch” (as the company behind the research referred to it) in their processes.

As it turned out, five areas seem to cause the biggest disruptions:

- Challenges with managing time and resources to ensure that procurement can handle the growing number of requests and internal initiatives.

- Lengthy approval workflows, resulting in long back-and-forth exchanges before contracts are negotiated, approved, and signed.

- Lack of transparent supplier communication.

- Lack of automation to help streamline repetitive and time-consuming tasks.

- Continuous spend analysis to help decrease costs while improving both, the efficiency and supplier relations.

The good news? You can overcome most of those challenges by implementing a handful of best practices within your procurement department.

Here are the five I recommend you implement first.

Procurement Best Practices – 5 Ways to Streamline Purchasing

#1. Automate procurement processes

Isn’t it a little bit ironic?

Procurement is one of the core business activities. Your work affects almost every aspect of the company’s operations and its bottom line. And yet, so often, purchasing teams have to work with outdated processes and tools to make it all happen.

Take a closer look at the list of the bottlenecks I listed above, and you’ll see it. Many of them are caused by nothing else but the department’s inability to process requirements quickly, without overloading staff with unnecessary and repetitive tasks.

How much easier would it be to manage resources if the team didn’t have to complete tedious activities by hand every time they process new requests? Or how many approvals could they get more quickly if they didn’t have to be involved in every step of the process?

Enter procurement automation.

All you have to do is define what you want to automate, and dedicated procurement automation software will take care of the rest.

Why implement procurement automation?

There are three main reasons:

- To save time, of course. Think of all those hours your team spends on processing purchase orders, data entry, approval follow-ups, invoice follow-ups, and more every week.

- To reduce human error. Automation will also reduce the potential for mistakes – even simple ones like miscalculated dollar amount or mis-entered order number.

- To complete processes faster. With most requests happening automatically, there are fewer chances for manual steps and accidental errors to slow down the process.

How hard is it to implement automation?

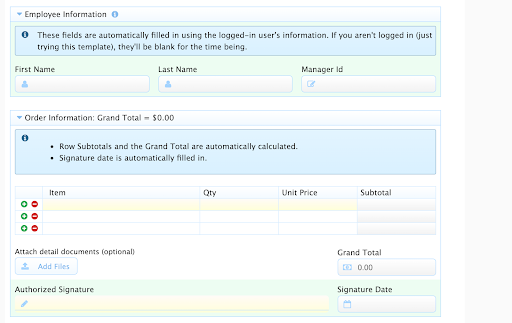

Actually, it’s not hard at all. Procurement automation software like frevvo features many pre-built purchase order templates that you could start with right away.

You can customize those templates to match your processes with a simple drag-and-drop designer. Or create specific processes – approval workflows, forms, and so much more – from scratch.

In fact, the only thing you need to get started is a well-defined workflow that you want to automate.

Want to automate your procurement processes?

Get started fast with pre-built templates and drag-and-drop tools. Sign up for your free 30-day trial.

This brings us to the next best practice I want you to know:

#2. Have well-defined processes

What’s the first thing that comes to mind when you think about processes?

For me, it’s efficiency. Processes should be efficient and create efficiency.

The thing is, for most organizations, inefficiency happens because the company lacks clearly-defined processes.

- Without well-defined processes, teams can’t be sure which tasks are essential at any given time, and what actions to prioritize to complete the work.

- Without clear processes, employees may struggle to streamline communications and manage project delivery between various stakeholders.

- And most importantly, without processes, companies let chaos creep into their operations.

In spite of inconsistent processes, things still get done, of course. Typically, however, at a much higher cost, in terms of money, efficiency, productivity, morale, and more.

Procurement processes aren’t immune to those problems either.

Without clear processes, duplicated requests amass unnecessary costs while poor record-keeping results in lost time, delays, and other delivery disruptions.

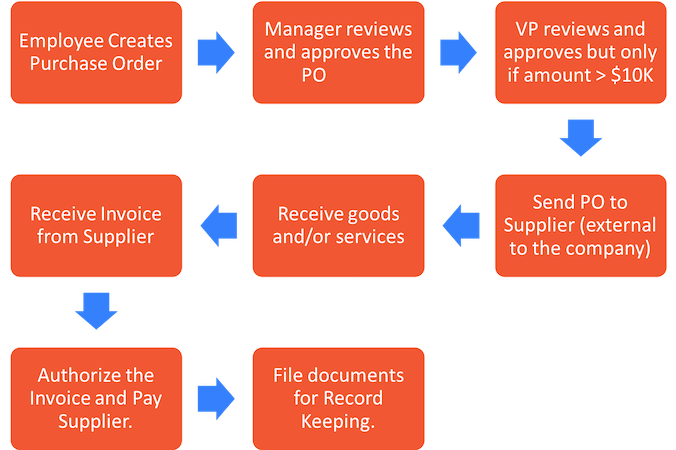

So, your next best practice to implement is to clearly define all your procurement processes.

- Document every step of the purchasing process,

- Identify who is responsible for each task, and

- Outline how those actions should be performed, step-by-step.

#3. Practice process transparency

This best practice follows what we’ve discussed above.

Transparency in procurement means giving all contract stakeholders – your team and all suppliers involved in a particular contract – access to relevant documentation to help them complete their respective parts seamlessly.

And the benefits of doing so are clear:

- Speeding up the process. When everyone knows what they need to do, and what standards or processes they must abide by, fewer bottlenecks happen.

- Cost reduction. Transparent procurement reduces costs by eliminating wasted time on long back-and-forth email chains, problems with purchasing orders, and bulk processing many requests.

- Accountability. Both yours and your vendor’s.

There’s one other benefit of transparency to consider: It helps instill responsible procurement practices.

Fully transparent processes help companies source products and services more responsibly, abiding by their corporate social responsibility.

#4. Have a centralized contract and documentation hub

Did you know that, on average, you and your team might be wasting up to 4.5 hours per week just trying to locate the right documents?

Another three hours go towards consolidating information from conflicting versions of the same document. And you might be spending up to 10 hours a week dealing with document inefficiencies.

That’s an incredible waste, isn’t it?

Inconsistencies across contracts, challenges with contract management, or even errors resulting from working with wrong contract templates affect your work.

However, many of those problems come as a result of a simple problem – not having a centralized destination where employees can find, access, and retrieve contracts and other necessary documentation.

Having all documentation – from operational processes to contract and other document templates – in a single, centralized location, ideally on the cloud and accessible from anywhere ensures:

- Consistency of contracts and communications,

- Fewer errors and time wasted on dealing with correcting inconsistencies.

If your organization regularly customizes procurement documents from templates, consider building a centralized hub containing all the required templates, as well as the most recent versions of the most commonly used contracts in one place.

You can use simple solutions, like templates repository within Google Docs or a dedicated contract management software.

#5. Use data to optimize inventory

I hear a lot from organizations struggling with determining optimal inventory levels. I get it. Inventory carrying costs can be enormous, after all. Logistics experts place it at 18% to 75% per year, depending on the business type.

So, given the constant push for control of spend and expenses at today’s organizations, you have to try to ensure the optimal stock level.

That’s where turning to data-driven insights comes in. Leverage advanced insights, and the power of AI, if possible, to determine optimum inventory at any given time, and predict the company’s needs for stock into the future.

Granted, the process involves implementing additional technology solutions. By tagging items with RFID, for example, you can track their stock in real-time, and get automated alerts when there is a need to resupply.

Data gathered in the process will help you accurately predict the demand, avoiding either overstocking or undersupplying an item.

Key Takeaways

A typical sourcing process requires constant and streamlined cooperation between far too many stakeholders to keep the process seamless at all times.

So, bottlenecks arise, and the resulting delays and disruptions affect both the company’s operations and the bottom line.

Luckily, certain best practices in procurement help eliminate many of the challenges above:

- Implementing procurement automation,

- Defining Processes

- Instilling Transparency in the Procurement Process

- Building a Centralized Contract and Documentation Hub, and

- Using Data to Optimize Inventory.