Picture this. You’re famous for your pasta sauce, yet it’s become so popular that you simply can’t produce enough. So, you hire a team of chefs to help you scale production.

But every batch of sauce tastes different, even though everyone uses the same ingredients.

This is likely due to poor process planning. The ingredients list is only half the recipe — you need a solid step-by-step method to create consistent results.

The same goes for your business processes.

If you don’t create repeatable, communicable, business processes that everyone can follow and understand, you’ll find you get different outcomes every time. This will result in lots of wastage, added costs, and time delays.

There’s a methodology to crafting a process that delivers consistent results each time.

Read on to understand who’s involved in process creation and how to create a process that produces the same outcome every time.

To jump ahead in this comprehensive guide to the section that you’re most interested in, click below:

- Why Is It Important to Create Processes?

- Who’s Involved in Creating a Process?

- How to Create a Process: Step by Step

Why Is It Important to Create Processes?

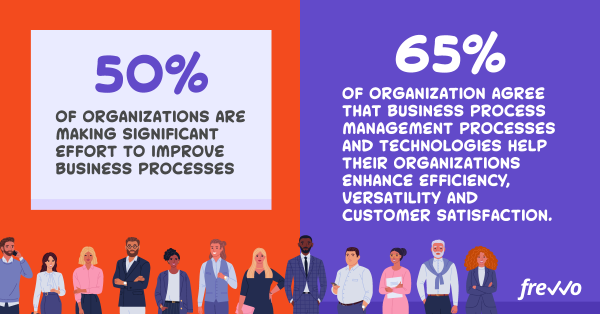

Currently, 50% of organizations are making a significant effort to improve business processes.

Why? Because effective processes increase efficiency.

In fact, 65% of organizations agree that business process management (BPM) tactics and technologies improve overall efficiency, versatility and customer satisfaction.

By creating official processes, you standardize operations so that you produce consistent results. This makes training far simpler, since staff follow the same process every time.

First, this saves time.

Take Cricket Australia, for example.

Before implementing frevvo to streamline invoicing processes, Cricket Australia took over 15 minutes to raise every invoice.

Now, thanks to business process automation software, Cricket Australia can raise hundreds of invoices a month without breaking a sweat.

What’s more, by creating robust processes, you can save money.

In fact, 70% of the companies are working on honing their processes to reduce costs and improve productivity.

Andrew White, chief of police at Clearlake PD, confirms this: “The frevvo platform enabled us to implement a cost-effective solution in record time to continue effectively serving our community in these challenging times.”

Streamlined business processes also help to eliminate errors, reducing wastage and delays.

All in all, this leads to improved customer relationships. According to 30% of firms, they’re working on improving their business processes to increase customer satisfaction.

Who’s Involved in Creating a Process?

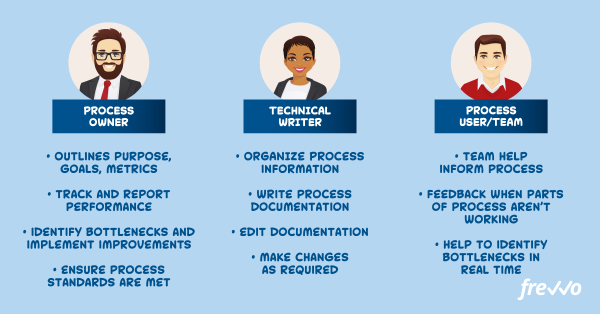

There are three main parties involved in creating every process: the process owner, the team or users who will be implementing the process, and a technical writer.

The process owner is responsible for outlining the purpose and goal of the process, along with defining the metrics for success.

The process owner tracks the performance of the process to determine whether it’s succeeding or if it needs improvements. By tracking the process, the owner can identify bottlenecks as they occur.

It’s also up to the process owner to make sure staff completing the process meet the required standards. This means making sure that everyone is properly trained and following protocols as outlined in the documentation.

The process owner will often enlist the help of the team or users who will be implementing the process. These actors are best at identifying what’s needed, since they regularly carry out the process.

Users will also provide feedback when using the process, to help the owner understand its efficacy. Since users are on the frontline, they’re usually the first to identify a bottleneck and report it back.

A technical writer will organize all information about the process and document it in easy-to-follow steps.

The technical writer is also responsible for editing documentation and updating it if processes change.

How to Create a Process: Step by Step

To iron out inefficiencies in your business, you’ll need to create effective, repeatable processes and communicate them to relevant staff.

Here’s how you go about creating a process in 11 easy steps.

1. Identify the Process

To start, you’ll need to identify the process you need to put in place or improve, then write a brief description outlining its purpose and benefits.

If you’re creating a process from scratch, this may mean pinpointing routine tasks that your staff complete in different ways, resulting in inconsistent outcomes.

For example, you might notice that your customer service staff members deal with support calls differently, leading to varied levels of customer satisfaction.

Alternatively, perhaps your accounting staff invoice customers differently each time, resulting in them frequently leaving off key information.

2. Outline the Scope of the Process

By outlining the scope of the process, you set boundaries on what it will cover. That way, you’re not overlapping into other areas of operation and you can measure the process’s efficacy more accurately.

The scope should define both what the process will cover and what it won’t cover.

For example, say you’re creating a sales process for answering general inbound sales calls. You might note that this covers all inbound calls from small and medium businesses, but that this process isn’t relevant for large, enterprise customers.

You should explain the impact that the process will have on other operations, as well as any operations that may impact the process.

For example, say that you change your delivery process so that all deliveries leave the warehouse on Fridays in one large shipment, instead of lots of small shipments throughout the week. This will impact the logistics of picking and packing orders.

Last, specify the limits of the process. When does the process kick in and when does it end? What signifies that the process is complete?

3. Identify Process Inputs

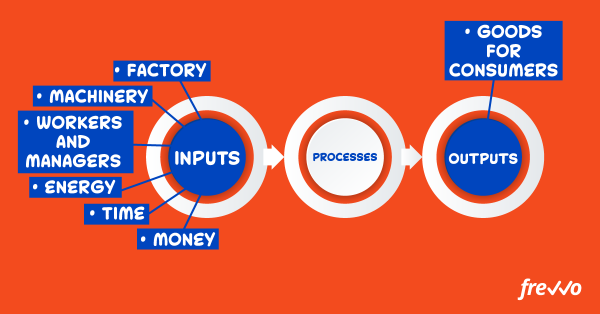

Process inputs are the resources that you put into the process to make it work.

By understanding your inputs, you can measure how viable a process is. If the returns outweigh the inputs, you have a viable and effective process. If you have to put in lots of resources and the outputs are minimal, you’ll have to rethink the way your process operates.

First, consider all the physical resources that go into your process.

If you were looking at a manufacturing process, for example, this would include the raw materials, factory, components, and energy needed to run the machinery.

Next, consider the labor you need, such as your factory workers, managers, and machinery engineers.

Now, add up the financial resources needed to carry out the process. How much does the machinery cost? What are you paying your staff? How much will the energy bills come to?

Finally, consider the time that goes into the process. People often forget to factor in time, but if a process takes too long, you’ll risk customer satisfaction and shell out lots in labor costs.

4. Identify Process Outputs

Outputs are the outcomes you get from your process.

List everything that’s produced by your process, both intentionally and unintentionally.

It’s important to include the unintentional outputs as these may affect the viability of your process.

For example, when manufacturing a product, you may produce harmful emissions. This leads to extra costs that come from dealing with these harmful emissions. Worse still, the emissions may be so harmful that it’s not safe to complete the process.

When listing your outcomes, consider both physical returns, like the goods you produce, and actions, such as the movement of goods.

5. Research Process Needs

Before you start laying down the steps of your process, you need to identify the requirements.

Work with the team who will use the process as well as any other stakeholders who may be affected.

Analyze the current situation and explore any issues with how things work. Note down what’s missing and what could be improved. You may also want to collect data on existing operations to understand where and when major issues occur.

Discuss potential solutions and visualize the prospective process with your team.

At this stage, you’ll need to research these potential solutions to understand their feasibility. Look to your competition to see how others in the industry carry out these operations. Equally, research potential technologies that could help automate and streamline the process.

6. Consider the Stages in the Process

Consider what needs to happen throughout the process to get the outcome you want and break the process down into bite-size chunks.

For example, say you’re looking at your procurement process. You know that you need protocols to approve procurements, a way for staff to request the procurement of goods, and steps to actually procure goods.

Once you have your smaller chunks, delve into each process step to work out the exact actions that will take place.

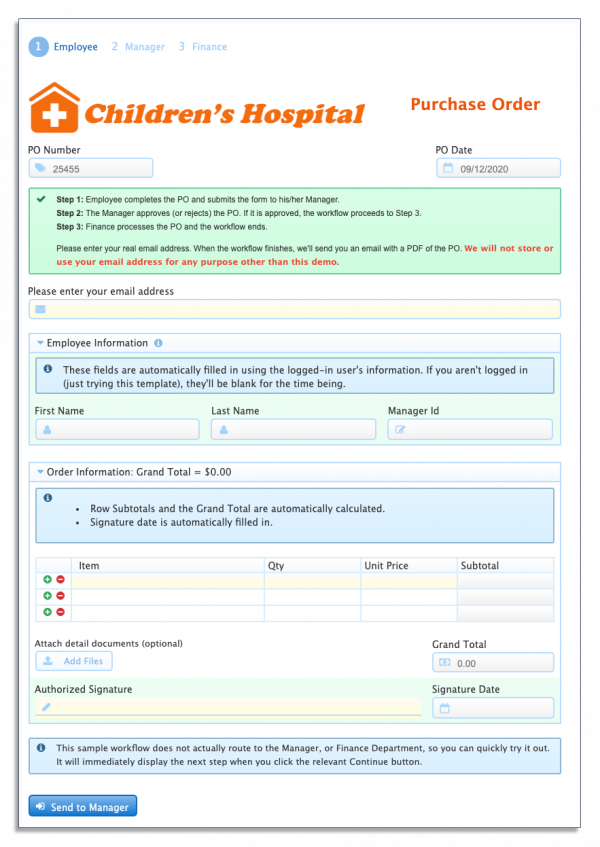

Take the procurement example. How will staff members request the purchase of goods?

You may decide that staff members should fill out a digital purchase order form. Consider the information that needs to go on that form for this phase to be effective.

7. Identify the Process Operatives

While some processes are carried out by one person, others may include whole teams or could even work across departments.

Knowing who is involved with which task helps you work out the most practical routing for your process. It also helps you to identify places where processes continually bottleneck.

Consider each task and identify the individual, team, or department responsible for completing the process.

Work out who will be responsible for documenting at each step, as well as anyone who may have to approve certain activities.

8. Order Your Process

Once you know what needs to be done and by whom, you need to order the tasks in your process.

At this stage, you need to identify the inputs and outputs of each phase.

Going back to the procurement example, your first stage would be a procurement request from a member of staff.

At this stage, the input would be a blank purchase order. The output would be a completed purchase order.

You need to map where these outputs go and to whom.

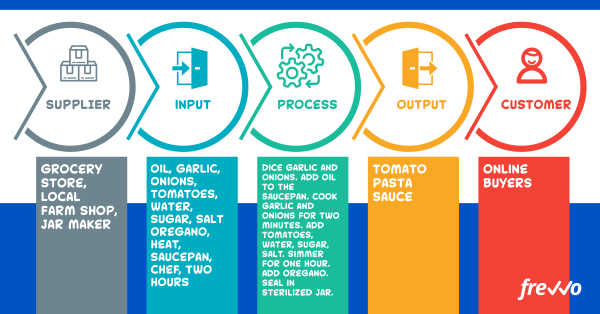

One of the best ways to visualize this is by creating a Supplier, Input, Process, Output, and Customer (SIPOC) process map.

At each stage you need to work out:

- Who supplies the information or resource for this phase?

- What information or resource (inputs) do they supply?

- What happens to this information or resource?

- What’s the result (outputs) of these actions?

- Who will this be delivered to?

9. Digitize the Process

Nowadays, it seems foolish to rely on manual processes since they’re slow and error-prone. That’s why 70% of organizations use BPA tools for process modelling.

Digitizing your processes lets you automate routing and automatically validate information to check that everything is correct. In fact, 75% of process experts agree that BPM technologies help their organizations reach their goals.

Digitization also means the stakeholders in your process can access information from anywhere. This is particularly ideal for remote teams.

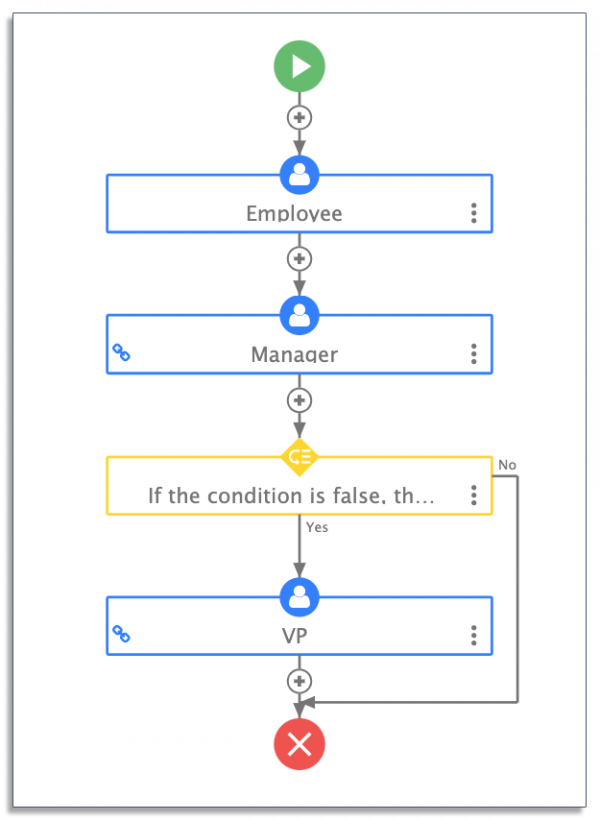

Most business process automation software, like frevvo, create a Business Process Model and Notation (BPMN) flowchart to map processes.

A BPMN process flowchart makes it easy to see the flow of your process and the operatives responsible for each stage.

10. Communicate the Process

Communication is key to making sure your staff members are on the same page and that processes are carried out the same way each time.

Document all stages of the process and create instructions on how staff should follow them. Make documentation easy to access and keep it up-to-date.

Remember to update process documentation whenever there’s a change and communicate this change to relevant staff.

To keep processes running effectively, it’s important that communication is two-way. Create a system where staff can report issues and offer suggestions for improvement.

11. Monitor Process Performance

If you’re not tracking the performance of your process, you won’t understand how well it’s doing or where there’s room for improvement.

By tracking performance, you’ll be able to identify bottlenecks immediately. This will help you to implement tweaks to the process as you go along.

Identify key metrics to track and schedule times to conduct reviews. Consider what the process is improving and how, along with any unforeseen impacts that may be occurring.

Conclusion

Once you know how to create a process, you can keep a far better eye on the performance of each aspect of your business.

Since everyone’s on the same page about how to perform each process, you’ll stamp out inconsistencies and enjoy the same outcomes every time.

Remember, it’s important to communicate processes in a way that everyone understands. If process documentation isn’t kept up-to-date, staff members may continue to use outdated processes, leading to inconsistent outputs.

If you’d like an easy method to create and automate processes, try frevvo’s 30 day free trial. It’s simple to create, communicate, and change processes in one easy-to-use platform.

The post How to Create a Process That Produces Consistent Results appeared first on frevvo Blog.